Description:

Application:

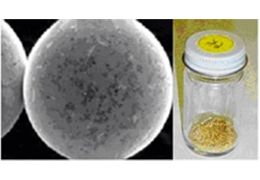

Copper spheres are used in Ball Grid Array (BGA) applications and attached to the chip with a high-melting alloy. The copper micro-spheres produce a controlled stand-off. The superior properties of copper make these spheres ideal for replacing traditional tin/lead alloys for lead-free applications.

Features:

Copper spheres are harder than soft solder bumps and offer a lower resistance path which has become increasingly desirable as frequency is pushed ever higher. The copper BGA system can enable easy testing and rework. Furthermore, copper spheres are perfectly round and virtually free from craters, cracks, and other surface defects.

Materials:

BOW Electronics uses a manufacturing process that produces the smoothest, roundest, tightest diameter copper spheres from Oxygen Free High Conductivity (OHFC) copper balls.

Size and Tolerances:

Copper spheres are available from 0.015"

Diameter: +/- 0.0002"

Sphericity: +/- 0.0004"

Uniformity: 0.0002"

Finish: 5 micro"

Plating:

Copper spheres can be plated with elements such as Sn and Ni in various thicknesses and finishes according to customer specifications. Common plating tolerances are .000150-.000250 and .000225-.000375. Call for your needs.

| Composition: | ||

| Copper (+ Silver) | 99.95 min. | |

| Residual Deoxidants | None | |

| Physical Constants | ||

| Density, lb/cu in. (At 68ºF) | 0.323 | |

| Specific gravity | 8.94 | |

| Melting point, ºF (Solidus and Liquidus) | 1981 | |

| Specific heat, Btu/lb/ ºF (At 68ºF) | 0.092 | |

| Thermal coef. Expansion/ ºF | (68-212ºF) | 9.4 x 10 6 |

| (68-392ºF) | 9.6 x 10 6 | |

| (68-572ºF) | 9.8 x 10 6 | |

| Thermal conductivity, btu/lb/ ºF (At 68ºF) | 226 | |

| Electrical resistivity, * Ohms/cir mil ft (At 68ºF) | 10.3 | |

| Electrical conductivity *† % IACS (At 68ºF) | 101 | |

| Modulus of elasticity, psi (Tension) | 17 x 10 6 | |

| Modulus of rigidity, psi | 6.4 x 10 6 | |

| *Annealed | ||

| † Volume and weight basis, minimum value | ||